TTK Ortho offers the B-PTM Integrated Hip system which includes a rich variety of components types and sizes and, therefore, offers a near custom fit for most patient pathologies. An integrated system provides a great number of surgical options. In the event of the need for the revision of a component of an integrated system, the need to remove properly functioning, well fixed, components is eliminated.

There are three types

EFFECTIVE DESIGN

- TiN Ceramic UltraCoat® on Head reduces Wear and Friction

- Minimization of Femoral Head Truncation - Optimizes Head Function

- Neck Aligned with Peak Load Vector - Optimizes Neck Function

- Collar Slots Ease Removal

- Collar, Set Perpendicular to Peak Load Vector - Optimizes Load Transfer

- Proximal, BioCoat® Porous Coating - Provides More Physiologic Calcar Loading

- Proportional Sizing and Cylindrical Geometry - Reduce Torsional Restriction and Thigh Pain

- Titanium Alloy with UltraCoat® Provides Superior Mechanical and Biological Compatibility

- Straight Stems in 1mm increments - Allow Precise Fit without Fear of Wedge Fracture

- Optional Stem Extensions provide Distal Fixation - Options for Trauma, Revision, and Osteoporosis.

Resurfacing Component

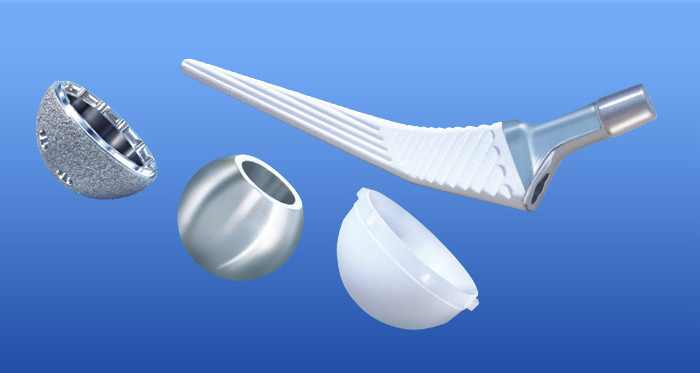

The Integrated Hip System consists of three matching components. The size of the components used is governed by the Acetabular Component size which is determined by the best acetabular fit. The Bearing Insert and Femoral Component sizes are then selected to fit the Acetabular Component. This avoids over-reaming of the acetabulum, common in earlier designs.

A major mechanical disadvantage of a surface replacement approach is that the larger head size substantially increases torque and wear compared to a conventional hip replacement. Recent studies of TiN Ceramic UltraCoat® coated titanium on UHMWPE, however, indicate that the articular friction of a surface replacement head can be reduced below that for Co-Cr alloy heads.

Furthermore, weare in a TiN-UHMWPE system and only a small fraction of that in a Co-Cr-UHMWPE system. Thus, all metallic components of the system are made of TiN Ceramic UltraCoat® coated titanium alloy. The TiN Ceramic UltraCoat® coated titanium resurfacing cups now make hip resurfacing a viable option for the young, active, patient.

The fixation surfaces of the components are covered with BioCoat® sintered bead porous coating with a mean pore size of about 350 microns. The short tapered femoral stem is uncoated to avoid stress shielding of the bone.

Femoral resurfacing components available in 11 sizes are matched to acetabular implants available in outside diameters from 46 to 70mm, in 2mm increments.

Femoral Stem

Primary load carrying prosthetic elements should be aligned with the applied load for optimal performance. Further, prosthetic design should seek to approximate as closely as possible the physiological loading of the bone to which the prosthesis attaches.

Stems available in 9 to 16mm in 1mm increments in both porous coated and non-porous coated versions.

Acetabular Components

TTK Ortho provides several acetabular cup systems to meet surgeons and patient needs. All systems are finished with UltraCoat® for superior biocompatibility and designed for reliability and simplicity. This approach provides optimal intraoperative options for primary and revision cases.

Fixed Acetabular Cup System

Anatomical cup configuration approximates the shape of the acetabulum and is recessed within its bony borders to minimize impingement and maximize range of motion.

Hemispherical Acetabular Cup

Bearings available with 15° inferior, anatomic flares for increased femoral head coverage; UltraCoat® on metal shell for improved biocompatibility and minimization of backside wear; Retention of subcondryl plate; Sizes from 46 to 62mm in 2mm increments

- Spherical interface surface with BioCoat® requires minimal bone resection and provides ease of acetabular preparation and intraoperative position adjustment.

- Inferior flares increase head coverage and flexion stability.

- Cup aligned with peak load vector optimizes range of motion and interface loading conditions.

- Acetabular cup accommodates resurfacing, 28mm and 32mm diameter bearings; Available in outside diameters from 46 to 70mm, in 2mm increments.

Femoral Head

Femoral heads are often truncated for manufacturing convenience since it is easier to grind and polish truncated heads. Unfortunately, such truncation reduces the spherical surface available to resist bipolar cup dislocation and can introduce undesirable stress risers in the UHMWPE bearing thereby increasing wear and possibly pitting the bearing surface.

TTK Ortho's proprietary machining and polishing processes allow maintenance of the maximum amount of spherical surface avoiding problems associated with truncation and providing maximum resistance against bipolar cup separation.