- As the primary refinement, all the metal components of the B-PTM knee is coated with an advanced coating method to increase the wear and scratch resistance. The coating method is TiN ceramic UltaCoat®, a standard at TTK Ortho

- The superior engagement of the B-PTM tibial bearing with the femoral component makes the use of a posterior stabilized (PS) device unnecessary. Since PS devices are characterized by highly excessive post against cam stresses, lack of axial rotation, failure in providing full flexion and other problem, such devices are undesirable

- This system, including the revision knee system, contains a wide variety of components allowing optimal treatment of a wide range of pathologies.

Cobalt

Gold

FEATURE & BENEFIT

An Advanced Technology Approach for Integrated Systems

TTK Ortho's advanced computer integrated manufacturing (CIM) system makes possible the rapid and economical design and manufacture of a large variety of orthopaedic devices. Thus, TTK can offer the B-PTM Knee Replacement System which includes a rich variety of components types and sizes and, therefore, offers a near custom fit for most patient pathologies.

An integrated system provides a great number of surgical options. In the event of the need for the revision of a component of an integrated system, the need to remove properly functioning, well fixed, components is eliminated.

Advanced Surface Modification Technology

Recent advances in surface modification technology have made, in our opinion, titanium alloy the metal of choice for orthopaedic implants. New, diamond hard, extremely adherent and corrosion resistant TiN ceramic coatings make titanium greatly superior to cobalt chromium alloy in reducing UHMWPE wear as well as superior in corrosion resistance and biocompatibility. TTk Orto offers premium UltraCoat® on all metal implants.

COMPONENT DESCRIPTION

TRICOMPARTMENTAL FEMORAL COMPONENT

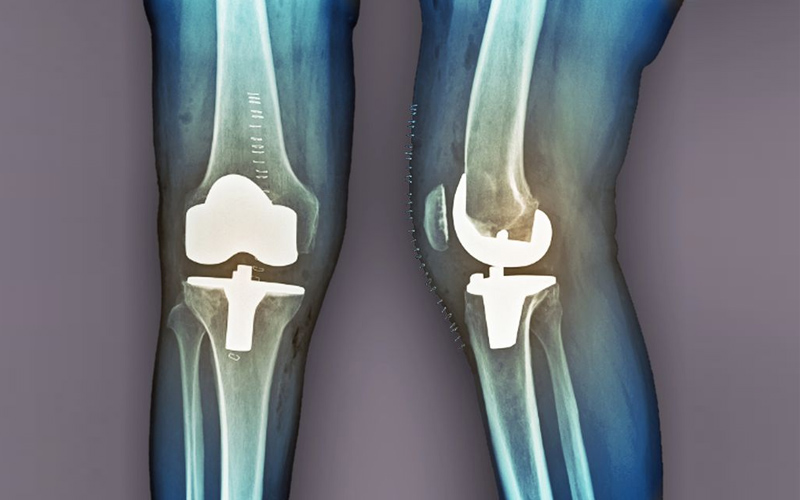

The Femoral Component is designed to replace the complex geometry of the femoral articular surface while maintaining an anatomical valgus angle. The radii of curvature decrease from anterior to posterior in a coordinated fashion to provide full flexion while maintaining excellent bearing congruity with the tibial component. Its geometry also congruently accommodates varus-valgus and rotary motions as well as providing congruent contact for the patellar components or the natural patella. The B-PTM femoral component has a 20° greater fully congruent tibiofemoral range of motion than the current LCS device. Full patellofemoral contact is retained for an additional 20° as well. Further, improved articulating surface accuracy and fit improve the congruity of the articulating surfaces in the B-PTM component.

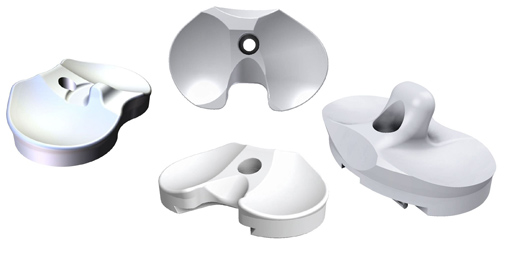

PATELLAR COMPONENT

The Patella Component consists of a patella bearing mounted on a metallic anchoring plate. The bearing congruently matches the spherical anterior flange segments and sulcus of the femoral component. This component allows for variations in anatomical position as well as surgical misalignment. The metallic anchoring plate is used to protect the prosthesis-cement and prosthesis-bone interfaces.

UHMWPE PATELLAR COMPONENT

This component provides fully congruent contact on its lateral facet except near full extension where contact pressures are low. The medial facet, which sees much lower loading, is in line contact with the femoral component.

TIBIAL BEARING

This component is used in the absence of viable cruciate ligaments to provide functional stability by use of proper tension control of the surrounding soft tissues of the knee. Excellent bearing congruity and superior dislocation resistance is provided. These bearings come in a variety of thicknesses to allow flexibility in bone resection of the tibia, to correct gross deformities, and can be extremely useful in revision arthroplasty. A modular bearing with a removable stem is available to ease bearing replacement with the metallic components in situ.

TIBIAL COMPONENT

This plateau is intended for use with the Tibial Bearing.

UHMWPE TIBIAL COMPONENT

The all poly device is available for low demand patients. This device is superior to other competitive products in use with regard to providing lower contact stresses.